-

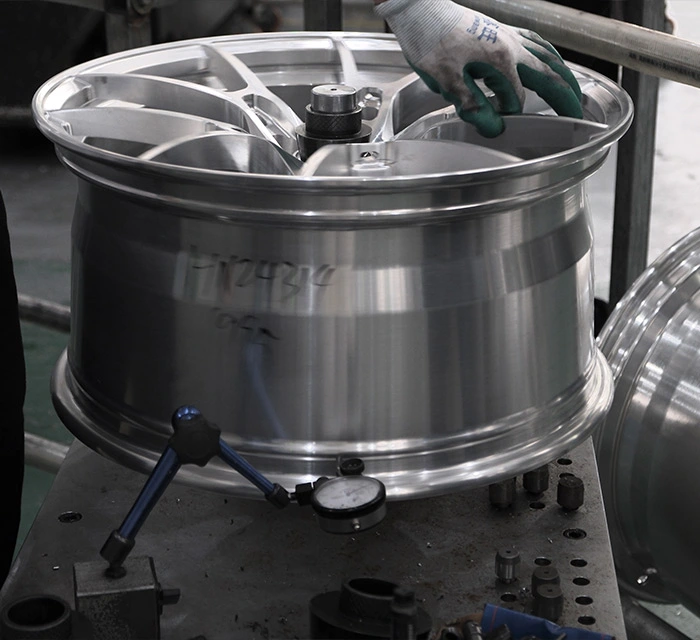

1. Vehicle Data Collection

OEM wheel measurements using professional modification data for perfect fitment.

-

2. Performance Profiling

Load rating analysis and weight optimization targets for enhanced performance.

-

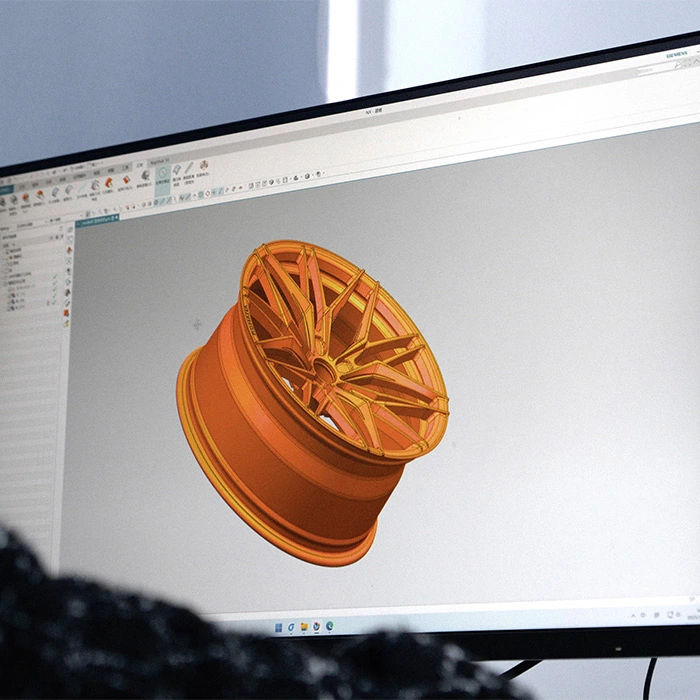

3. Design Selection

Spoke pattern selection (Y-spoke/multi-spoke/deep concave) with 3D render provided. Multiple finish options including diamond cutting, chrome, polished, or brushed finishes.

-

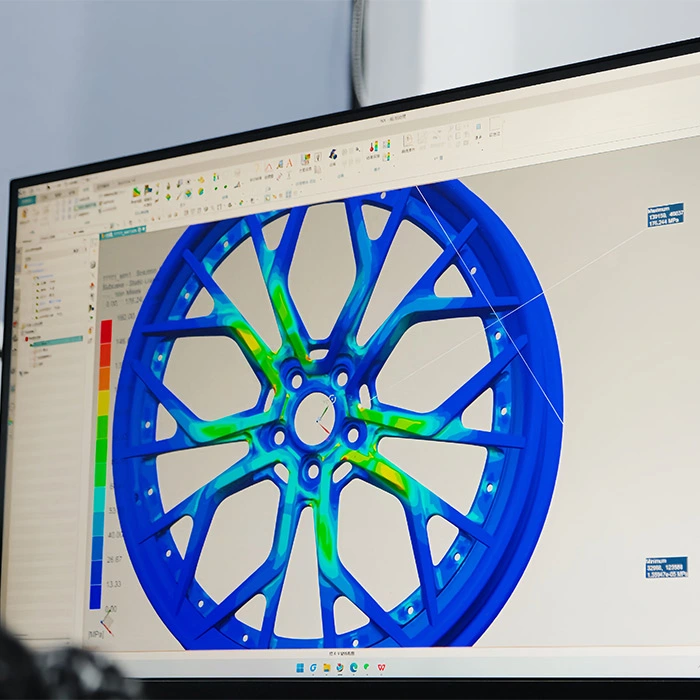

4. CAE Simulation

ANSYS structural analysis with 2x GVWR impact simulation. Fatigue life prediction exceeding 1 million cycles at 1,200Nm torque for maximum durability.