Our manufacturing facility is certified under the ISO 9001 International Quality Management System. The design and production processes at Olim Forged strictly adhere to globally recognized industry standards, including TSE, VIA, and JWL certifications, ensuring uncompromised quality and compliance across all operations.

We offer the following disk production times:

Designing the 3D model :2-3Days

Production time starts from the moment the 3D model is approved and the advance payment is paid

Production cycle

monoblock:15-20Days

2-Piece Forged Wheel:25-35Days

3-Piece Forged Wheel: 30-45Days

If there is any change, it will be notified in advance when ordering

Terms do not include delivery time!

Discover the sophisticated OLim collection, a harmonious blend of aesthetic elegance and premium functionality designed for contemporary vehicles. Designed for discerning drivers who want to elevate their on-the-go experience through a seamless integration of sophisticated style and exceptional driving dynamics, the collection redefines automotive excellence by transforming every drive into an expression of innovative and refined performance.

Submit your project brief today to initiate a collaborative, data-driven journey toward creating your signature forged wheels.

From concept to delivery, we handle every detail with aerospace-grade precision.

Wheels engineered to amplify your vehicle’s capabilities, not just its aesthetics.

Certifications include ISO 9001, JWL, and TÜV homologation for worldwide road legality.

Crafted from aircraft-grade 6061-T6 forged aluminum, our wheels deliver an exceptional strength-to-weight ratio (UTS ≥310 MPa) while reducing unsprung mass for enhanced vehicle dynamics.

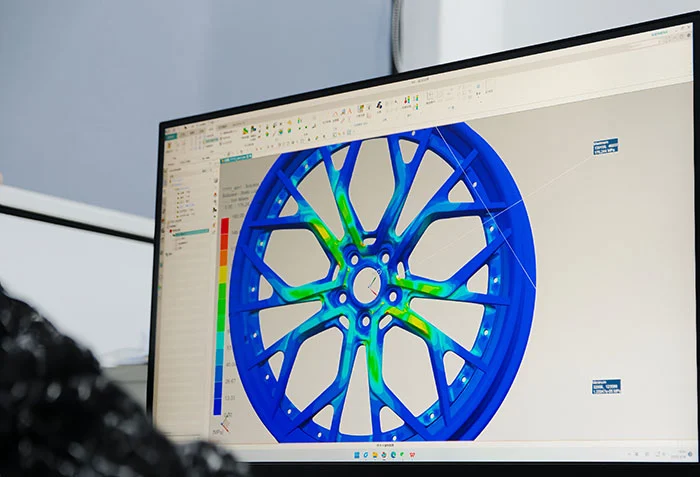

Structural integrity is assured through multi-axis FEA/CAE simulations, validating fatigue resistance, impact safety (JWL/VIA-certified), and load capacity under extreme driving conditions.

Lightweight architectures are optimized via topology optimization, reducing rotational inertia by 15-20% to improve acceleration, braking, and fuel efficiency without compromising durability.

Every wheel is precision-machined to ±0.03mm tolerances using 5-axis CNC systems, tailored to your specific bolt patterns , offsets, and center bore requirements.

Direct compatibility with factory TPMS sensors and lug nut configurations ensures plug-and-play installation across European, Asian, and North American vehicle platforms.

• Monoblock Construction: Single-billet design for maximum stiffness (≥22,000 Nm/° torsional rigidity)

• Two-Piece Assemblies: Hybrid builds featuring forged aluminum centers with carbon fiber barrels (3K weave, autoclave-cured)

Select from diamond-cut spokes, brushed, polished finishes – all precision-engineered to OEM corrosion resistance standards.

All systems meet TÜV Rheinland regulations, backed by a 5-year structural warranty.

Engineered for those who equate motion with emotion.